Mabowo

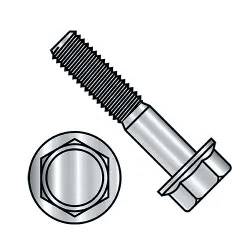

Maboti a flange ndi mtundu wa wothamanga wopindika wokhala ndi chingwe chozungulira pansi pamutu. Chingwe chimathandizira kugawa katunduyo pamalo okulirapo ndipo amathandizira kuti atsimikizire kulumikizana ndi kodalirika.

-

Chitsulo chosapanga dzimbiri chopanda kanthuKanthuPhapa pang'ono

COMCOTIMIMIMICM Mitundu: Makina osapanga dzimbiri

Zinthu: Zopangidwa kuchokera ku 18-8 / 304/316 zosapanga dzimbiri, zomangira izi zili ndi malamulo abwino azamankhwala ndipo zitha kukhala zovuta kwambiri. Amadziwikanso ngati chitsulo chosapanga dzimbiri.

Mtundu wa mutu: mutu wa hex woyatsira.

Kutalika: amayezedwa pansi pamutu.

Mtundu wa ulusi: ulusi wouma, ulusi wabwino. Zingwe zopondapo ndi miyendo yamakampani; Sankhani zomangira izi ngati simukudziwa phula kapena ulusi pa inchi. Zingwe zabwino ndi zowonjezera zimapakidwa kwambiri kuti muchepetse kugwedezeka; Wopanga ulusi, wabwinoko kukana.

Kutumiza: Kugawidwa kwachangu komwe mawuwo amakumana pamwamba, ndikuchotsa kufunika kwa omwe amapatula osiyana. Kutalika kwa mutu kumaphatikizaponso flange.

Muyezo: Zolemba zamkati zimakwaniritsa miyezo yapa ASM F5933 ndi IFI 111 Miyezo.

Zingwe za metric zimakumana ndi miyezo ya din 6921.Ulusi wopindika M5 M6 M8 M10 M12 M14 M16 M20 d P Phula Ulusi wamiyala 0,8 1 1.25 1.5 1.75 2 2 2.5 Ulusi wabwino-1 / / 1 1.25 1.5 1.5 1.5 1.5 Ulusi wabwino-2 / / / 1 1.25 / / / b L≤125 16 18 22 26 30 34 38 46 125 <l≤200 / / 28 32 36 40 44 52 L> 200 / / / / / / 57 65 c min 1 1.1 1.2 1.5 1.8 2.1 2.4 3 da Pangani a max 5.7 6.8 9.2 11.2 13. 159.7 17.7 22.4 Fomu b max 6.2 7.4 10 12.6 15.2 17.7 20.7 25.7 dc max 11.8 14.2 18 22.3 26.6 30.5 35 43 ds max 5 6 8 10 12 14 16 20 min 4.82 5.82 7.7 6.78 11.73 13.73 15.73 19.67 du max 5.5 6.6 9 11 13.5 15.5 17.5 22 dw min 9. 12. 15.8 19.6 23.8 27.6 31.9 39.9 e min 8.71 10.95 14.26 16.5 17.62 19.86 23.15 29.87 f max 1.4 2 2 2 3 3 3 4 k max 5.4 6.6 8.1 9.2 11.5 12.8 14.4 17.1 k1 min 2 2.5 3.2 3.6 4.6 5.1 5.8 6.8 r1 min 0.25 0,4 0,4 0,4 0,6 0,6 0,6 0,8 r2 max 0,3 0,4 0,5 0,6 0,7 0,9 1 1.2 r3 min 0.1 0.1 0.15 0,2 0.25 0,3 0.35 0,4 r4 ≈ 3 3.4 4.3 4.3 6.4 6.4 6.4 8.5 s Max = kukula kwa Nonil 8 10 13 15 16 18 21 27 min 7.7 6.78 12.73 14.73 15.73 17.73 20.67 26.67 t max 0.15 0,2 0.25 0,3 0.35 0.45 0,5 0,65 min 0,05 0,05 0.1 0.15 0.15 0,2 0.25 0,3 -

304 Chitsulo Chopanda Chitsulo Chopanda ChingweKanthuPhapa pang'ono

Flange ndi yozungulira, yathyathyathya pansi pamutu wa bolt. Zimathetsa kufunika kwa omwe akupatukana nawonso ndikupereka malo ochulukirapo. Mabotolo oyaka amatha kukhala ndi mitundu yosiyanasiyana ya ma flanges, monga kusunthidwa kumangika zowonjezereka kuti zikuwonjezereka ndikulimbana ndi kugwedezeka, kapena kusakhazikika kumalumikizana ndi malo okwanira. Kupezeka mosiyanasiyana, kutalika, ndi zingwe zolumikizira kuti zigwirizane ndi zochitika zingapo.

Ulusi wopindika M5 M6 M8 M10 M12 M14 M16 M20 d P Phula Ulusi wamiyala 0,8 1 1.25 1.5 1.75 2 2 2.5 Ulusi wabwino-1 / / 1 1.25 1.5 1.5 1.5 1.5 Ulusi wabwino-2 / / / 1 1.25 / / / b L≤125 16 18 22 26 30 34 38 46 125 <l≤200 / / 28 32 36 40 44 52 L> 200 / / / / / / 57 65 c min 1 1.1 1.2 1.5 1.8 2.1 2.4 3 da Pangani a max 5.7 6.8 9.2 11.2 13. 159.7 17.7 22.4 Fomu b max 6.2 7.4 10 12.6 15.2 17.7 20.7 25.7 dc max 11.8 14.2 18 22.3 26.6 30.5 35 43 ds max 5 6 8 10 12 14 16 20 min 4.82 5.82 7.7 6.78 11.73 13.73 15.73 19.67 du max 5.5 6.6 9 11 13.5 15.5 17.5 22 dw min 9. 12. 15.8 19.6 23.8 27.6 31.9 39.9 e min 8.71 10.95 14.26 16.5 17.62 19.86 23.15 29.87 f max 1.4 2 2 2 3 3 3 4 k max 5.4 6.6 8.1 9.2 11.5 12.8 14.4 17.1 k1 min 2 2.5 3.2 3.6 4.6 5.1 5.8 6.8 r1 min 0.25 0,4 0,4 0,4 0,6 0,6 0,6 0,8 r2 max 0,3 0,4 0,5 0,6 0,7 0,9 1 1.2 r3 min 0.1 0.1 0.15 0,2 0.25 0,3 0.35 0,4 r4 ≈ 3 3.4 4.3 4.3 6.4 6.4 6.4 8.5 s Max = kukula kwa Nonil 8 10 13 15 16 18 21 27 min 7.7 6.78 12.73 14.73 15.73 17.73 20.67 26.67 t max 0.15 0,2 0.25 0,3 0.35 0.45 0,5 0,65 min 0,05 0,05 0.1 0.15 0.15 0,2 0.25 0,3